Computer simulations are changing the standards in vehicle design. They allow engineers to depict physical phenomena and so to minimise the need for costly prototypes. What opportunities do these technologies offer, and how do they impact efficiency, safety, and innovation in the automotive sector?

Computer simulation plays an important role in the vehicle design process, especially in times focused on cost optimisation and innovation. They allow for accurate replication of physical phenomena, enabling engineers to conduct tests without the need to build physical prototypes. This makes the vehicle design process faster, more efficient and cost-effective.

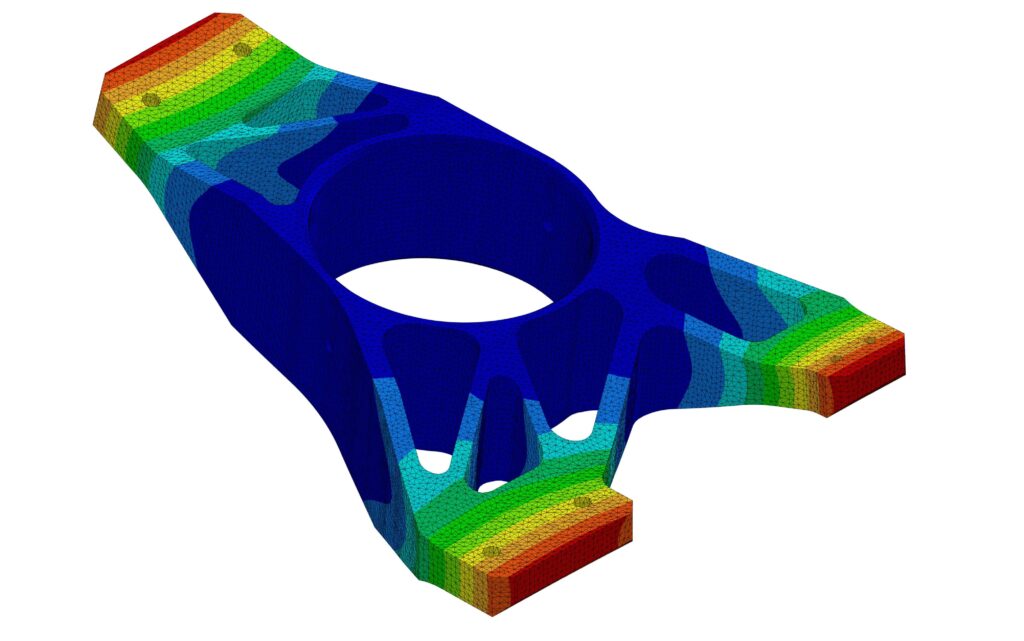

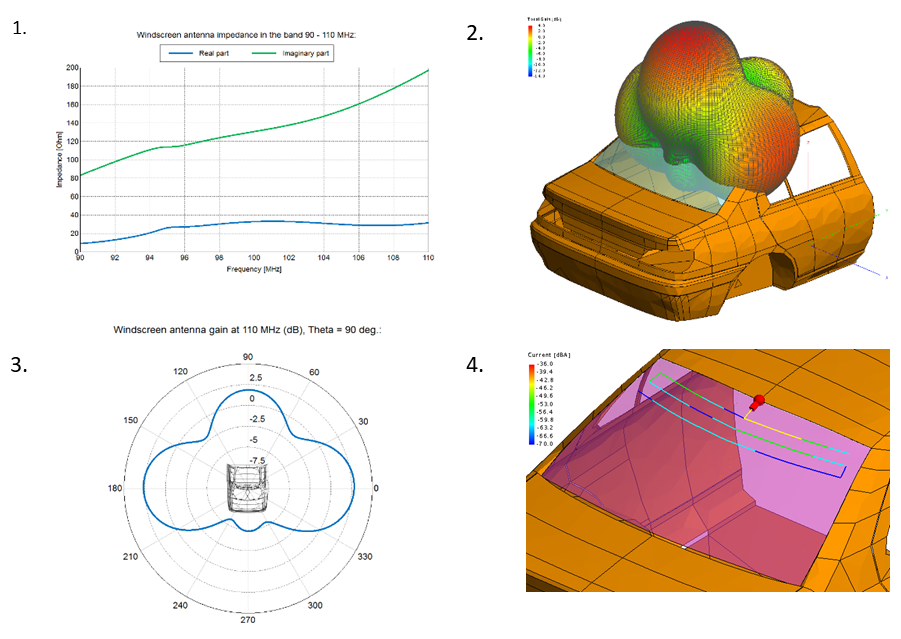

In the context of automotive design, computer simulation refers to the process of creating virtual models that reflect real-world physical and mechanical phenomena, allowing tests to be conducted without constructing physical prototypes. Simulation models are based on real-world data and, thanks to modern algorithms, can replicate a wide range of vehicle operating scenarios. Computer simulations for engineers allow the modeling of various aspects of vehicles, from aerodynamics to structural integrity, as well as thermal and acoustic analysis.

Computer simulations have gained great popularity in the automotive industry because they allow solutions to be tested in a safe and cost-effective manner, without risk to personnel and equipment. Types of computer simulations used in the automotive industry include crash tests, running simulations, as well as strength and reliability proof of vehicle components. These simulations can be used to predict vehicle behavior under different road conditions and reduce the risk of failure.

Computer simulation is widely used in the various phases of vehicle design. From the initial concept stages to advanced testing, simulations enable engineers to optimise vehicle structures for durability, energy efficiency and safety. One of the main simulation applications of simulations is in body design, where they help to determine aerodynamic properties, crashworthiness and the optimal vehicle structure.

In the automotive field, simulations are also invaluable in the interior design process, where they help assess ergonomics, acoustic comfort and thermal properties of the cabin. Testing various interior materials and insulation in a virtual environment allows for the creation of optimal conditions for both drivers and passengers.

Computer simulations of physical phenomena are key in the dynamic vehicle testing. Engineers can accurately analyse the vehicle’s driving behaviour, steering and braking responses, as well as modeling the effects of various external conditions such as varying loads or uneven road surfaces. This allows to predict potential design problems in advance and to adapt the vehicle for demanding operating conditions.

The automotive industry employs various types of simulations that cover different aspects of vehicle operation. Among the most important are:

Although computer simulations are extremely advanced, they do not completely replace physical testing. Numerical analyses make it possible to reduce the number of prototypes and real-world tests, but do not eliminate them entirely. CAE (Computer-Aided Engineering) simulation services offer the possibility to run computer simulations under near-real conditions, allowing for better verification of the results in later whole-vehicle tests under real-world conditions.

However, physical testing still plays a key role in the acquisition of material properties or vehicle certification, especially where detailed analysis of results is required. Simulation and real-world testing work together, creating an efficient and safe process for vehicle design and testing.

The benefits of computer modeling and simulation in automotive are substantial. Primarily, they allow for significant cost reductions and shorten the vehicle design timeline. Simulations enable engineers to quickly test different scenarios without the need to build expensive prototypes, thus accelerating the introduction of new vehicle models to the market.

Simulations also increase the safety of designed vehicles. The ability to thoroughly test each design element under different conditions makes the final product more reliable. Moreover, simulations help minimise the risk of manufacturing defects that could lead to costly recalls or service actions.

Computer simulations are an integral part of modern industrial design in the automotive sector. They enable the use of advanced mathematical algorithms to test, analyse and optimise vehicles, allowing for the creation of safe, efficient, and innovative products. As a leader in automotive engineering, Endego offers comprehensive CAE simulation services, supporting companies at every stage of vehicle design and testing. With our advanced tools and expertise, we help clients create the vehicles of the future.

Also check out our other services:

The past few years have been challenging for the European automotive sector – production declines, supply chain disruptions, and intensifying competition from Asian manufacturers have forced many companies to downsize. Now, as the market slowly begins to recover, businesses face a new challenge: how to quickly restore their delivery capacity when skilled specialists are in short supply?

Read moreModern automotive lighting is no longer limited to a purely functional role. LED logos, illuminated grilles, and dynamic light animations are becoming a new communication language for car brands. How does the combination of design and technology turn light into a recognizable brand signature?

Read moreA few decades ago, securing a car meant a sturdy lock and an alarm. Today, it means defending a rolling, always-connected computing platform – equipped with dozens of Electronic Control Units (ECUs), multiple in-vehicle networks, and high-speed links to the cloud.

Read more