Redesigning a vacuum valve used in the production processes of e.g. TV screens and mobile phones.

Redesigning a vacuum valve used in the production processes of e.g. TV screens and mobile phones.

Redesigning a vacuum valve used in the production processes of e.g. TV screens and mobile phones.

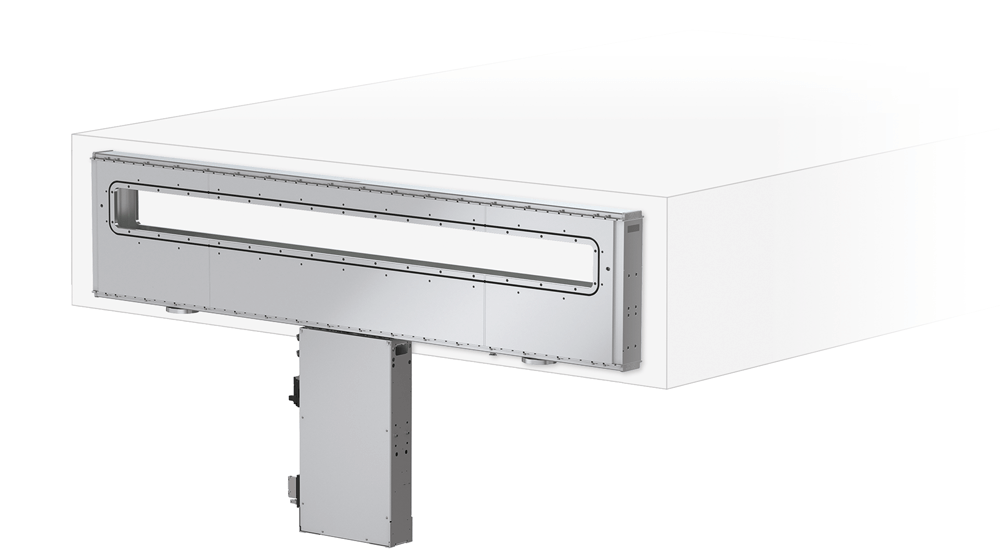

The project focused on reducing the number of parts, changing the manufacturing technology, optimising the dimensions of individual components and optimising the assembly process of the entire valve.

The activities resulted in reducing the weight of the entire valve, shortening the assembly time and, ultimately, lowering the cost of the product.

The past few years have been challenging for the European automotive sector – production declines, supply chain disruptions, and intensifying competition from Asian manufacturers have forced many companies to downsize. Now, as the market slowly begins to recover, businesses face a new challenge: how to quickly restore their delivery capacity when skilled specialists are in short supply?

Read moreModern automotive lighting is no longer limited to a purely functional role. LED logos, illuminated grilles, and dynamic light animations are becoming a new communication language for car brands. How does the combination of design and technology turn light into a recognizable brand signature?

Read moreA few decades ago, securing a car meant a sturdy lock and an alarm. Today, it means defending a rolling, always-connected computing platform – equipped with dozens of Electronic Control Units (ECUs), multiple in-vehicle networks, and high-speed links to the cloud.

Read more